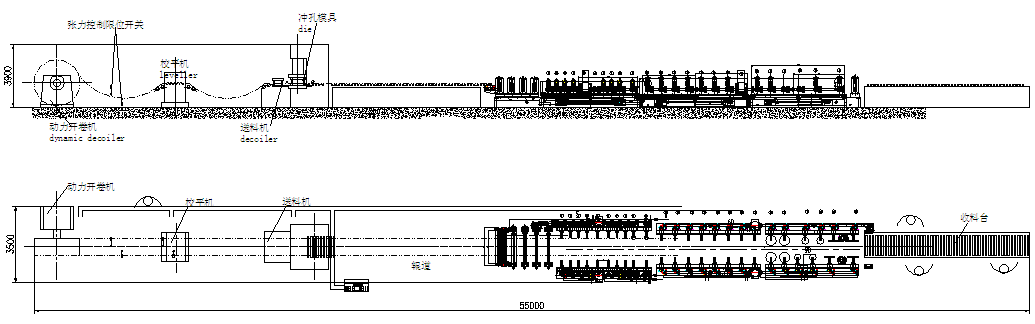

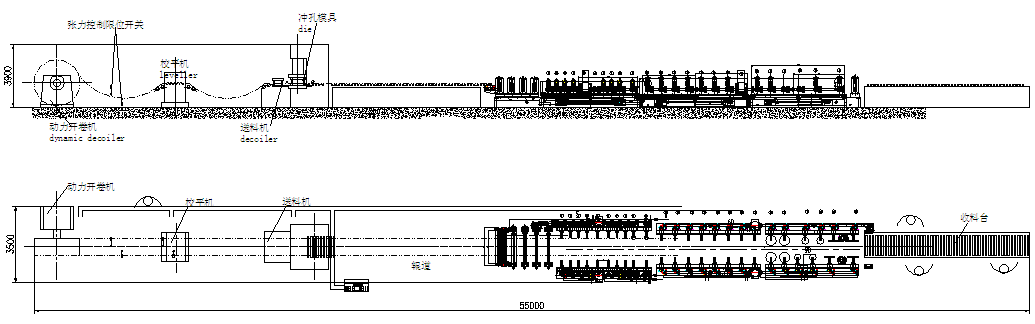

Medium duty (25mm Return Flange) Cable Tray Roll Forming Production

Machine Line manufacturer

Main technical parameters

1.1 Technical parameters of machine

1.1.1 Area of production line: length 50m x width 4m x height 5m

1.1.2 Feeding direction: from left side to right side

1.1.3 Power: 380V, 50Hz, 3 phase

1.1.4 Pneumatic station: pressure 0-0.7MPa.,0.5M3/min.

1.1.5 Hydraulic oil: 46# Hydraulic oil

1.1.6 Gear oil: 18# gear oil

1.1.7 Color: blue

1.2 Main technical parameters

1.2.1 Width of material sheet:120-940mm

1.2.2 Thickness of material sheet: 0.8~2.0 mm

1.2.3 Line speed with punching: 3-6M/min

1.2.4 Length of finished product: 3m

1.2.5 Total power: about 78KW;380V50HZ

2. Forming product range

2.1 Cable tray Maximum thickness:1.0~2mm

Cable Tray Roll Forming Machine

| No. | Name | Type and size | Quantity | (KW) Power(kw) |

| 1 | De-coiler | | 1 set | |

| 2 | Straightener | | 1 set | 4 |

| 3 | Servo-feeder | | 1 set | 4 |

| 4 | Punching Press | YANGLI GROUP | 1 set | 25 |

| 5 | Punching Mould | | 1 set | |

| 6 | Conveying Table | | 1 set | |

| 7 | Roll Forming machine | Full automatic control type | 1 set | 15 |

| 8 | Collection table | | 1set | |

| 9 | Electric Control System | | 1 set | 7.5 |

Main forming machine

a. Type: double hanger gearing drive. Forming width is adjusted by

automatic forming wall moving, it also can adjust height quickly.

b. Insert the sheet plate which already perforated into the

machine, through 18 stations to roll as the cable tray. It consists

with the speed regulation alternating current machine, reducer,

high-precision linear rails, gearbox (left and right side), the

crosswise adjusting mechanism and one complete set of rollers. One

set of roller can complete all type of the cable tray,type change

can through the adjustment of the one side of machine by motor. The

main body and the gearbox use the welding structure, de-stressing

processing; the material of the gear is the 45 steel hard tooth

surface. Forming technology of main forming machine is from Italy,

it will guarantee high-precision.

The roller uses the combinated structure, the speed difference and

the forming resistance are small, the steel plate surface will be

less wear; and also guaranteed the precision shape of the working

piece with no scratch .The material of the roller is the GCr15

forging, after whole quenching then by numerical control

processing, degree of hardness can reach HRC58-62; Has the

characteristic with high strength, hardness, precision and long

service life etc.

Electric control system

a. Full line is controlled by PLC control system with touch screen

operation to achieve the human and PLC interactive. The operator

can monitor the setting program (programmable control) and modify

the parameter to control the line. Also can check the running

status, parameter and error indication etc...

b. Operation type: manual /auto two type switch. In manual

position: can run the each part of the machine. In auto position:

can run the full line. The emergency stop ensures the safe of the

equipment and operator.

c.Machine side is equipped with the manual operation control panel

for convenient worker to operate;

Control styp: manual handle

4,Produce condition

capability: about 71.5kw

gas fountain: 0.9 cube/min

Production land area: 33m*3m

5,Machine Parameter

| NO. | Project | Unit | Parameter | Remark |

1 | Material | Type | High strength steel | | |

| Strength of material sheet | Map | ≥350 | |

| Thickness of material sheet | mm | 1.2~2.0 | |

| 2 | Size of production | mm |

Reference the picture | |

| 3 | Production speed | m/min | Punching speed 4m/min

Forming speed 10m/min | |

| 4 | Material of roller | | GCr15 quenching treatment | |

| 5 | Drive type | | Gear | |

| 6 | Power | kw | About 75 | |

| 7 | Electric control system | | PLC variable frequency control | |

| 8 | Dimensions(Length*width*height) | m | 55X4X3.9 | |