VCD FRAME ROLL FORMING MACHINE

Content:

1 - Work piece diagram

2 - Machine Layout

3 - Technical Specification

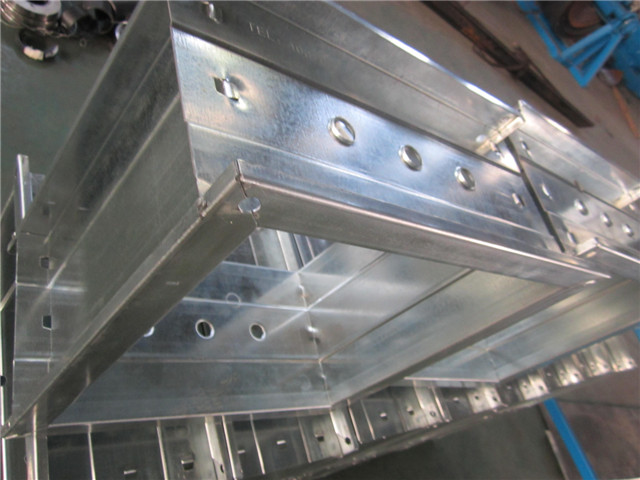

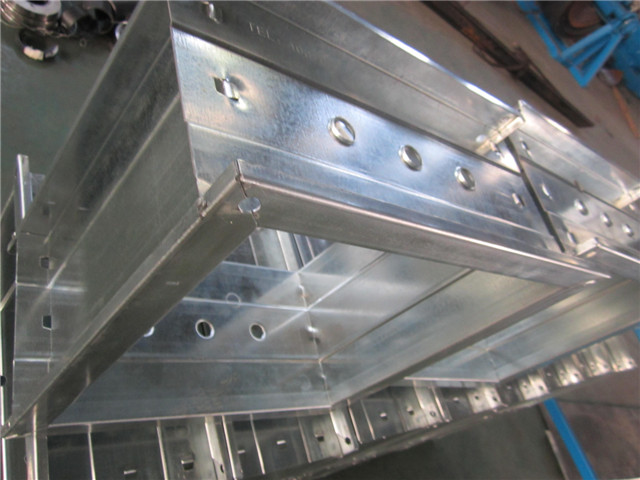

4 - Machine and work piece photo

Workpiece Diagram:

Material:G.I or Stainless steel

Thickness:G.I 1.0 - 1.6 mm

S.S 0.8 - 1.2 mm

Raw Material width:228 - 231 mm

Machine Layout:

Technical Specification

1.Equipment technique requirement:

1.1.Equipment floor space:23×3.0×2.5(L×W×H)meter

1.1.2 Equipment feeding material the orientation:The left side

enters and right leave

1.1.3 Voltage:380V, 50Hz, and 3phase

1.1.4 hydraulic oil:NO.46#

1.1.5Gear oil:18# Hypoid gear oil

2.Equipment main technical parameters:

2.1 Raw material width:Around 231 mm

2.2 material thickness:1.0~1.6mm

2.3 Material:Stainless steel:0.8~1.2mm;Galvanized sheet:1.0~1.6mm

2.4 Production speed:Around 6M/min

2.4 Production length:≥4000mm

2.5 Equipment total installed capacity:Around 25KW

3.1 De-coiler

Material width:≤250 mm;Material thickness≤2.0mm;Inner

diameter:480-520 mm;

Outer diameter:Φ1200mm;Max.Load capacity:≤2T

3.2 Servo feeding system (BNC-30)

BNC-30 Technical parameters:

- The feed shaft diameter:Φ60mm

- Measuring diameter of shaft:Φ60mm

- Maximum feed plate of width:≤300mm

- Maximum feed plate of thickness:≤3.5mm

- Maximum feed speed:≤40m/min.

- Feeding and blanking step length tolerance:±0.20mm,

- Feed products overall length tolerance:±0.25mm,

- Servo motor power/brand:1.8KW/ Japan Yaskawa.

- Transmission:Synchronous wheel / gear

- Length measuring encoder:ROUNDSS 2500P

3.3 Notching, punching hole and cutting

Structure:Hydraulic punching structure, the welded steel frame, has

good inflexibility

First notching dies:2 sets

First punching die:1 setAfter forming notching dies:2 sets

After forming cutting die:1set3.4 Main rollforming machine

- Forming steps:16 group

- Forming profile channel

- Forming framework:Use the wall type side plate, gear drive.

- Side wall thickness:35mm

- Max material width:≤231mm

- Min material thickness:1.6mm

- The roll shaft diameter:Φ48 mm

- Roller material:Cr12MoV.

- The quenching hardness:HRC58-62°

- Use of double bearing design, bearing type 6208

- The main drive motor uses 11kw frequency conversion motor.

3.5 Cutting system

A.Modality:Hydraulic cutting system

B.Design feature:Cutting machine designed to be after roll forming,

the cutting length and number of pcs can be set by using PLC.

3.6 Run-out table

Framework:Platform type,without power

3.7 Electrical control system

3.7.1 The whole line adopts PLC control, LCD touch screen display,

man-machine interface.Interaction between workers and PLC.

The operator can do theprogram setting of the PLC, modify the

control parameters and monitor the control process of the

production line and the running state real-time monitoring

equipment, operation parameters and fault indication.The length of

the work piece digital setting, the length of the work piece can be

adjusted.

3.7.2 Mode of operation:Manual / automatic.

In manual mode, automatic switching function should be in the

manual mode,

The machine will be in stand-alone operation for testing and

repairing work.

In automatic mode, all production and operation, the start up

sequence;Along with the emergency stop button, easy to handle

emergencies, to ensure the safety of equipment and personnel.

NO. |

Project |

Unit |

Parameters |

Remark |

1 |

Material | Type | | Mild steel Galvanized sheet | |

| Strength of material sheet | Map | ≥350 | |

| Thickness of material sheet | Mm | 0.8~1.5 | |

| 2 | Size of production | Mm |

Reference the picture | |

| 3 | Production speed | M/min | 6~8 | |

| 4 | Material of roller | | GCr quenching treatment | |

| 5 | Drive type | | Gear box | |

| 6 | Power | Kw | About 34 | |

| 7 | Electric control system | | PLC variable frequency control | |

| 8 | Dimensions(Length*width*height) | M | 28X4X3.9 | |