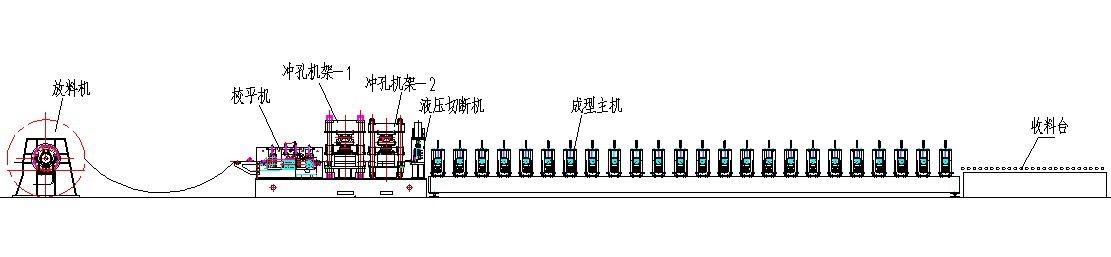

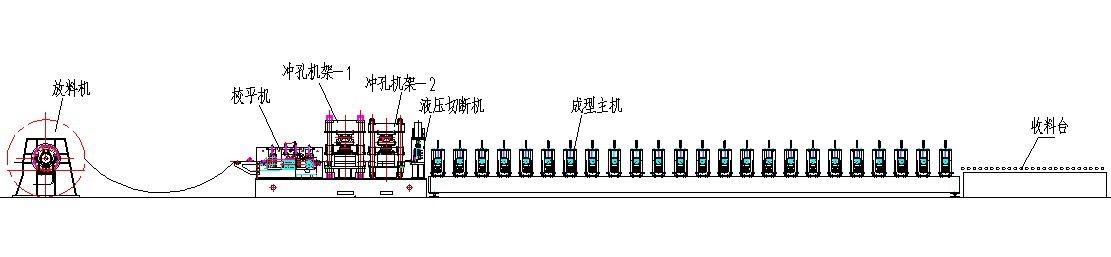

Equipment structure

It is composed of de-coiler, guide rack, leveler, flatting,

continuously punching machine, roll forming, correction,

cutting-to-length (punching), collection table, electrical control

system etc.

Unit performance

1, The thickness of material sheet: 1.5≤§≤2.0㎜

The width of material: 250≤§≤450㎜

2, Product speed: 10-12m/min

3, Occupy ground area: length 30m x width 3m

4, Total power: about35.5kw

Main Roll Forming Machine Working Craft

1. Technique parameters of the processing line

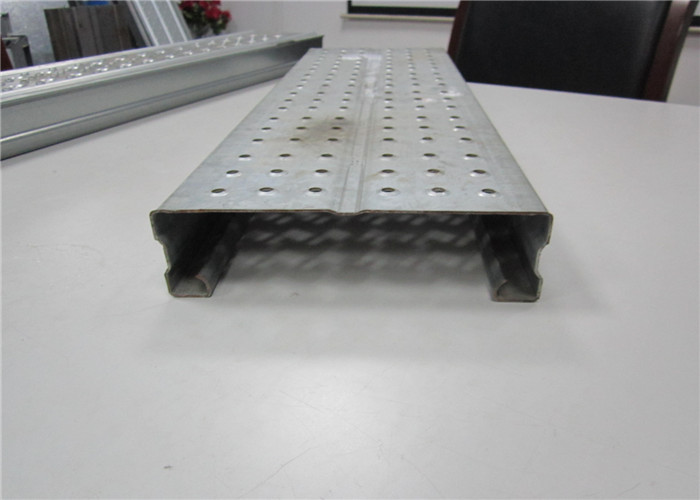

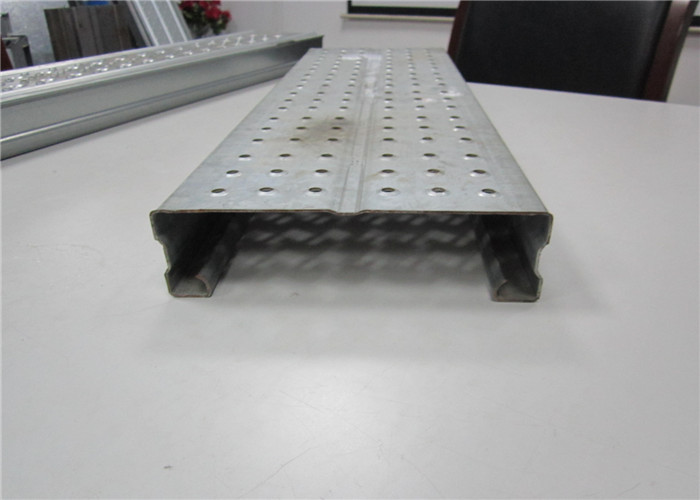

(1) Plate Material: Galvanized plate/strip steel

(2) Thickness of the plate : 1.5-2mm(different thickness is ok)

(3) Machine body :350mm H steel

(3) Wall thickness of the main forming machine: 18mm steel plate

(4) Outside debugging to change sizes

(5) Transmission chain : 2’’

(7) Reducer :15kw Xingxing Cycloid which works stably and no noise.

(8) Seam type semi-mat

(9) Roller material: GCr15 with quenched treatment 62-64°C

(10) Rollers: 16 steps including 9 shafts for leveling.

(11) 4 steps side wheels on the coil-input part for avoiding

coil-deviation

(12) Forming part adopts side wheel rotation forming to reduce

friction between rollers and coil. Easy and fast debugging

(13) Diameter of active shaft: 80mm, 45# steel

(14) Hydraulic pump power: 7.5KW

(15) PLC control systerm with inverter

,5 Main Roll Forming machine

1. Working speed :8-12 m/min

2. Material thickness :1.0-1.2mm

3. Control system:PLC

4. Decoiler :5T

5. Punching :one set

6. Main roll forming rollers:16row rollers

7. Roll material:GCR15 Steel after quenching process HRC58-62℃,he

chrome plating surface treatment

8. Material of the shaft and the shaft diameter:45# steel

processing, shaft diameter is 70mm

9. Main machine power :18.5kw

10. Hydraulic station power:5.5kw

11. Hydraulic pressure:24Mpa

12. Scissors punching material:Cr12Mov,Quenching HRC 58-62℃

13. Length tolerance:3m±1.0mm

14. Voltage :380V, 50HZ,3 phrase

15. driving mode :chain driving mode

16. Machine size :16.5*2.2*1.6m

17. Rolling speed:12-15m/min

18. Shaft diameter:Φ76mm

19. Material of cutting:Cr12Mov with quench HRC58-62°

20. Tolerance:10m+-0.5mm

21. Hydraulic station:5.5kw

Main Machine Parameter

| No. | Item | Unit | Data | Remark |

1 | Raw material | Type | | MSgalvanized sheet | |

| Strength of panel | Map | ≥350 | |

| Thickness of panel | mm | 1.2~2.0 | |

| 2 | Size | mm | See figure | |

| 3 | Speed | m/min | 6~8 | |

| 4 | Material of roller | | GCr15Hardening treatment | |

| 5 | Drive type | | Gear box | |

| 6 | Total power | kw | About 45 | |

| 7 | Electrical system | | PLC Inverter control | |

| 8 | Contour dimension(L*W*H) | m | 35X4X3.9 | |

The details of the scaffolding machine

| NO. | CONTENTS |

| 1 | Scaffolding plank standing tube welding device |

| 2 | Scaffolding plank ledger welding device |

3 |

Punching Device | Full automatic punching device |

| Semi-automatic punching device |

| Manual punching device |

| Spare part:punching mould |

4 |

diagonal brace flattening &punching device | Full automatic diagonal brace flattening &punching device |

| Semi automatic diagonal brace flattening &punching device |

| Manual diagonal brace flattening &punching device |

| Spare part:punching mould |

5 |

Tube cutting machine | Auto Blade cutting Device |

| Swing saw cutting device |

| Direct saw cutting device |

| Auto direct saw cutting device |

| 6 | Auto Scaffolding plank wedling line | Auto robot welding |

| Auto robot hand welding |

| 7 | Base jack & U-head jack welding device |

| 8 | Auto scaffolding plank roll forming machi |