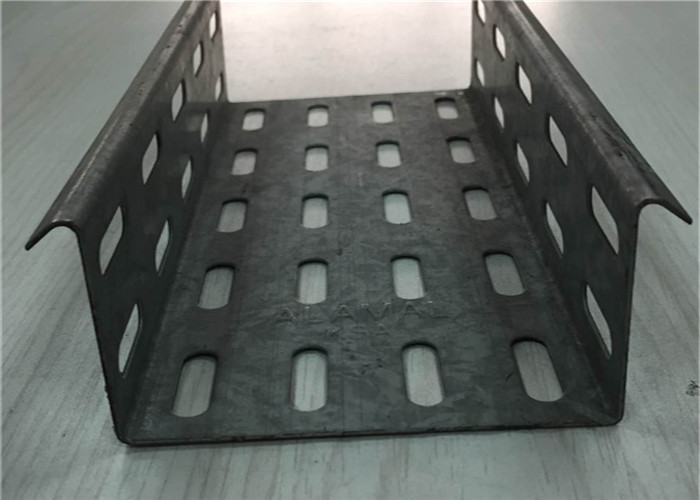

Building Material Galvanized Diamond U Lintel

Steel Lintel is a range of lightweight, easy to install, high load

bearing, hot dipped galvanized ribbed steel lintels for use with

brick construction in the building industry; specifically designed

to support brickwork above window and door openings in replacement

to conventional concrete lintel.

Roll Forming Machine Components:

Cold Roll Forming Machine Working Flow:

Decoiling→ Feeding & Guiding→ Leveling→ Pre-Punching/Cutting(If

needed)→Roll Forming→

Cutting→ Output Table

Machine Parameter

| NO. | Project | Unit | Parameter | Remark |

1 | Material | Type | High strength steel | | |

| Strength of material sheet | Map | ≥350 | |

| Thickness of material sheet | mm | 1.2~4.0 | |

| 2 | Size of production | mm |

Reference the picture | |

| 3 | Production speed | m/min | Punching speed 4m/min

Forming speed 10m/min | |

| 4 | Material of roller

| | GCr15 quenching treatment | |

| 5 | Drive type | | Gear | |

| 6 | Power | kw | About 75 | |

| 7 | Electric control system | | PLC variable frequency control | |

| 8 | Dimensions(Length*width*height) | m | 55X4X3.9 |

1, Equipment capabilities

It can according to the need to produce the steel width

(60mm≤§≤860mm), many kinds of specification electric cable bridges

and other structure product.

Product speed by punching: 2.55m/min

Continuous rollforming speed: 1015m/min

Material thickness: 1~2mm

Material require: Q235 cold roll steel

Production line has automatic and manual two operating mode, may

realize the linkage and the partition revolution work.

2, Main composition of machine

This unit consists of the decoiler, ML-900 flatting, 200 punch,

die, servo feeding, guider, main roll forming machine, follow

cutting, cut-to-length part, recoiler, electrical control cabinet;

etc.

Roll Forming Machine Product Feature:

They are all widely used in steel structure industry, decorating

and fitting material industry,

physical distribution and supermarket shelf industry,

transportation industry, wiring industry, electrical

equipment industry, elevator industry and various projects using

pipe industry.

3,Each part major technical parameters

Component list

| Name | Model | Quantity | Discription |

| 1.Decoiler | Cantilever model 5T | 1 set | Cantilever,hydraulic,passive decoiling, with pressing arm and coil

car. |

| 2.Roll forming system | Leveler | 1 set | Roller material:GCr15 steel being heat treatment, with

digital-controlled procession, which ensures the rollers’ hardness

to be HR60 and durable Shaft:#45 steel roller stands:column Motor drive,with chain connection&gear. Cr12 mould steel with quenched treatment 500T hydraulic presser,press at speed of 20 times /min,Power 30KW,

with 16sets of mould

|

| Punching | 1 set |

| Pre-punching system | 1 set |

| Servo feeder | 1 set |

| Guiding device | 1 set |

| Clamping roll | 1 set |

| Roll forming system | 1 set |

| Post-cutting system | 1 set |

| 3.Out put system | Supporting table | 2 sets | |

| 4.Hydraulic system | 1 set | The decoiler and main roll former share one station, presser use

another station. |

| 5.Electrical system | 1set | 1.PLC control,Encoder set length 2.interface:touchpad+button 3.AC inverter |