Shelf Upright Roll Forming Machine

BOSJ offer you the full range warehouse system products,BOSJ has a

profesional engineering and production team to work with you.

Product: Shelf column, Shelf crossbeam, Shelf stay rod, Shelf plywood etc.

Advantages of Heavy Duty Pallet Racking .

1. It is suitable to be used in factories, manufactures and

warehouse

2. Size(L*W*H): 1200/1500/2000*450/600/1000*1800/2000/2500mm

3. Perfect for storing categorized products in a neat and tidy way

4. heavy-duty shelf set for warehouse shelving

5. Strong structure,special desigin for the total fucntion

6. Easy installation

7. Customization is acceptable

8. High Working Efficiency

9. Long-Service Lifespan

Equipment capacity:

1, Equipment production capacity: width≤400mm, thickness of steel

material: 1-2.5mm

2, Production speed: 8-15m/min

3, Total power: about 21.5kw

Structure of Heavy Duty Pallet Racking.

Beams

Horizontal bracing

Diagonal bracing

Uprights

Screw, safe pins

Protector

Trays ,pallets ,or steel mesh plates

Main Machine Parameter

| NO. | Name | unit | parameter | remark |

1 | materials | type | | Mild steel,galvanized sheet | |

| Plate strength | Map | ≥350 | |

| Plate thickness | mm | 1.0~1.6 | |

| 2 | specification | mm |

See the pictures | |

| 3 | speed | m/min | 18 | |

| 4 | Material of the roller | | GCr15,Hardening treatment | |

| 5 | drive type | | Gear box | |

| 6 | power | kw | About 35.5 | |

| 7 | Electrical control system | | PCL frequency control | |

| 8 | Size(lengthXwidthXheight) | m | 20X4X3.9 | |

| Main Accessories |

| 1 | Decoiler | 1 set |

| 2 | Main Forming Machine | 1 set |

| 3 | Correction System | 1 set |

| 4 | Hydraulic Station | 1 set |

| 5 | Auto-Cutting system | 1 set |

| 6 | PLC Control System | 1 set |

| 7 | Run Out Table | 1 set |

Determinant of Heavy Duty Pallet Racking design

1. The weight of your goods (trays, steel containers / boxes are

included)

2. The dimension of your goods together with pallets ( Length Width

Height )

3. The maximum height of your forklift and the available height of

your warehouse

4. The dimension of your forklift,if you have,please offer us,we

will consider this fact.

5. The fork direction,if you have,please offer us,we will consider

this fact.

6. The dimension of your warehouse

7. The path of the transportation

Structure and performance of machine

Processing

Passive De-coiler---Leveler---Servo

feeder,Punching---Forming---cutting--Collection

Main structure and performance of machine

De-coiler Technical data

Width of material sheet:100~300mm;;Thickness of material

sheet:2.5mm;

Inner diameter: φ508mm Range of expanding: ф480-520 mm

Maximum outer diameter: φ1200mm, loading: ≤3T

Leveler

Working roller: Nine rollers type leveling machine

Feature of structure: after the quenching and tempering,

chrome-plating processing, the rigidity, surface roughness of the

roller etc. are all enhance greatly; It is composed by the clamping

roller and the leveling roller, the clamping roller may the

independent control, the leveler has one pair of horizontal guide

roller and two pairs of vertical guider roller and easy to adjust

by hand wheel.

Main forming machine

Forming stations:18stations(roller)

Type of profile(as photos)

Forming frame:Gantry type

Max. Feeding width:≤300㎜

Max. Feeding thickness:2.5mm

Roller axis:φ70 mm

Material of the roller:Gcr15,quenching treatment,HRC58-62°

Main drive motor:22kw frequency motor drive

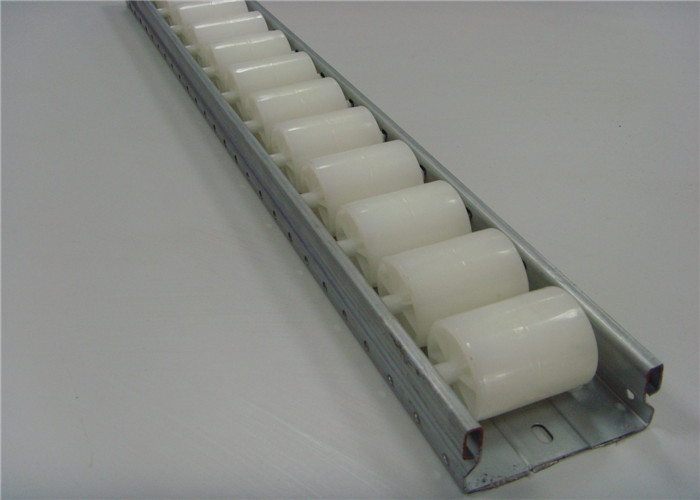

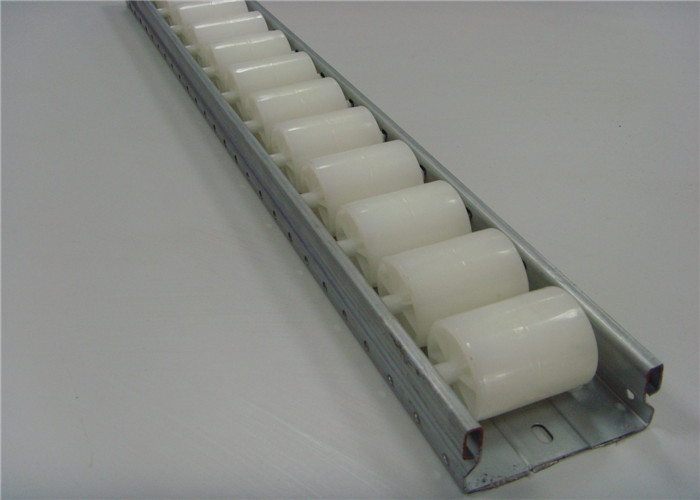

Cutting device

Structure:hydraulic cutting blade

Collection table

Structure:Roller type with no power

Product Pictures