Main technical parameters

1. General structure of equipment

Area of production line: length18m x width 3.5m x height 5m

Feeding direction: from left to right

Power: 380V, 50Hz, 3 phase

Pneumatic station: pressure 0-0.6MPa.,0.5m3/min.

Hydraulic oil: 46# Hydraulic oil

Gear oil: 18# gear oil

2. Technical parameters of machine

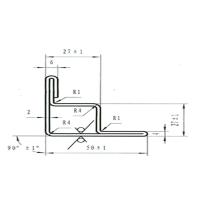

Width of material sheet:≤250 mm

Thickness of material sheet: 2.0mm

Material of sheet:Low carbon,etc

Punching speed:8-12m/min

Length of the work piece:2500 mm

Total Power:36KW.

Electric Cabinet PRODUCT FEATURE

Dimensions:Width: 600 mm /Height: 1600 mm/Depth: 600 mm

Installation height for components:33 U

Number of doors:1

Weight/PU:61.5 kg

PRODUCT DESCRIPTION

| Material: |

Enclosure frame: Sheet steel, 1.5 mm

Roof: Sheet steel, 1.5 mm

Front frame: Extruded aluminium sections with die-cast corner

pieces

Rear door: Sheet steel, 2.0 mm

Gland plates: Sheet steel, 1.5 mm |

Surface finish: |

Enclosure frame: Dipcoat-primed

Roof and rear door: Dipcoat primed, powder-coated on the outside,

textured paint

Front frame: Powder-coated

Gland plates: Zinc-plated |

Colour: |

RAL 7035 |

IK Code: |

IK09 |

Supply includes: |

Enclosure frame

Front frame (r/h hinge, opening angle 130°, held on the left via

mechanical snap fasteners)

Rear door (r/h hinge, may be swapped to opposite side)

Roof

Adaptor sections, 482.6 mm (19") attachment level

Gland plates

2 TS punched rails 18 x 38 mm |

| |

Forming craft

De-coiler----Leveler/feeder----Continuous punching---Roll

forming(welding)---Cutting-to-length---Collection

Equipment structure

This production line consist of de-coiler,leveler/feeder,Continuous

punching,Roll forming,Cutting-to-length,Collection and electric

control system,etc.

Bottom Continuous punching

Punching type:Four-column punching device

Punching mould material:Cr12

Roll Forming Machine

Forming stations:26 stations

Wall-frame structure or gantry type

Max feeding width:220mm

Roller axis diameter:¢60mm,,Material 40Cr

Roller material :GCr15,quenching treatment,Hardness HRC56-62º

Motor power:22kw

Wall-frame structure or gantry type

Max feeding width:220mm

Roller axis diameter:¢60mm,,Material 40Cr

Roller material :GCr15,quenching treatment,Hardness HRC56-62º

Motor power:22kw

Fly-cutting device without bur

Electric control system

Full line is controlled by PLC control system with touch screen

operation to achieve the human and PLC interactive. The operator

can monitor the setting program (programmable control) and modify

the parameter to control the line. Also can check the running

status, parameter and error indication etc...

Operation type: manual /auto two type switch. In manual position:

can run the each part of the machine. In auto position: can run the

full line. The emergency stop ensures the safe of the equipment and

operator.

Main Machine Technical Parameters

NO |

Item |

Unit |

Techncial Parameter | Remark |

1 |

Raw Material |

Type | | , | |

| Sheet Tensile | Map | ≥350 | |

Thickness | Mm | 1.5 | |

| 2 |

Size | Mm | | |

| 3 | Production Speed | M/min | 6~8 | |

| 4 |

Roller material | | GCr15 | |

| 5 |

Driven Type | |

Gearbox | |

| 6 |

Motor Power | Kw | 40 | |

| 7 | Electric Control System | | PLC | |

| 8 | Machine Size | M | 35X4X3.9 | |